An agronomist has invented a smart device which controls the cultivation process, provides what plants need, and give warnings and advice to farmers.

|

An agronomist has invented a smart device which controls the cultivation process, provides what plants need, and give warnings and advice to farmers.

As a made-in-Vietnam product, its price is just equal to 1/20 of the imports of the same kind.

The inventor Dr Nguyen Van Quy from Hue City Agriculture and Forestry University is a well-known name among agronomists. Several years ago, he invented a hanging garden system that grows clean plants for people who live in urban areas.

For the control unit, he and his co-workers received third prize at the Thua Thien – Hue 2017 provincial Technological Creativity Contest.

Quy said the control unit is not a new product. Similar devices are available in the market, but they are imports which cost VND60-80 million, and they have complex operation processes and are unsuited to Vietnam’s climate.

There are also domestically made products in the market, but they have few functions and cannot store information.

The unit created by Quy has many advantages – it is cheap, easy to operate and suited to Vietnam’s climate conditions.

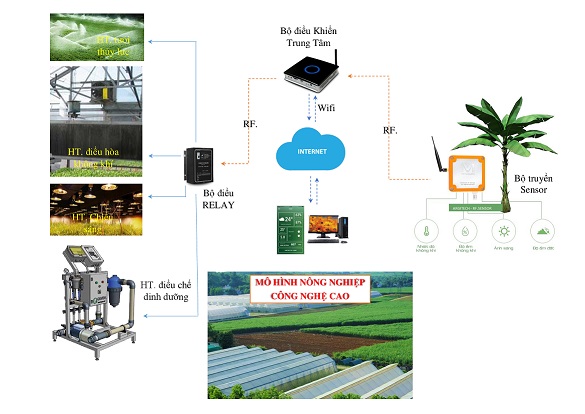

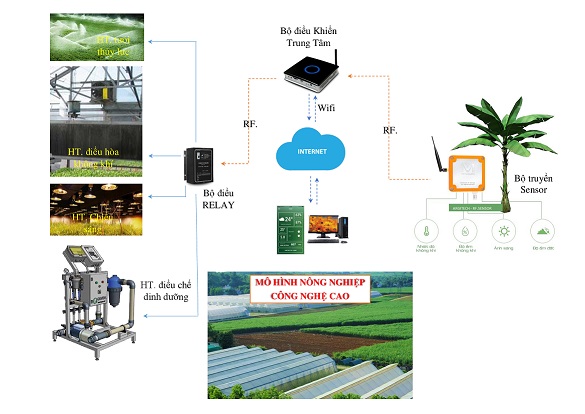

The device has four systems – information receiving, information processing, information transmission systems and a system to change environment conditions.

The operation principle is simple. There are nine sensors installed in the information receiving system, including temperature, air humidity, soil moisture and soil pH sensors, hung at some specific locations.

The sensors receive signals from the environment, encrypting them and transmitting the information with RF wave to the central control unit.

The environmental factors are displayed on screens and compared with ready-set factors.

After comparing the factors, the central control unit will make decisions on turning on the plant care equipment. The unit will also send signals to the LAN system to store all the information about the cultivation process.

Quy said when designing the product, he had to think carefully about which technologies to choose.

Wireless technology (RF wave) was chosen to connect sensors, the central control units and the equipment to change environment conditions. The use of wireless technology will help expand the sphere of sensor installation, thus collecting information in larger sphere.

The other strong point lies in the wifi transmission system. The integration of the system stores information to better serve the cultivation process and product traceability.

Regarding the production cost, Quy said it is priced at VND5 million, just equal to 1/20 of imported products.

“With the price of VND5 million and the life cycle of five years, farmers will have to pay VND2,740 a day for amortization. The total cost they have to pay will be VND3,740 a day if counting the spending on electricity. If noting that the equipment can replace two workers, farmers would be able to save VND396,000 a day,” he said.

(Source: VNN)

![[Photo series] Admiring the most beautiful riverside road in Dong Nai before its technical traffic opening](/file/e7837c02876411cd0187645a2551379f/012026/nen_20260114174655.jpg?width=500&height=-&type=resize)