Apple Inc on Monday unveiled a robotic system called Liam to take apart junked iPhones and recover valuable materials that can be recycled, such as silver and tungsten.

|

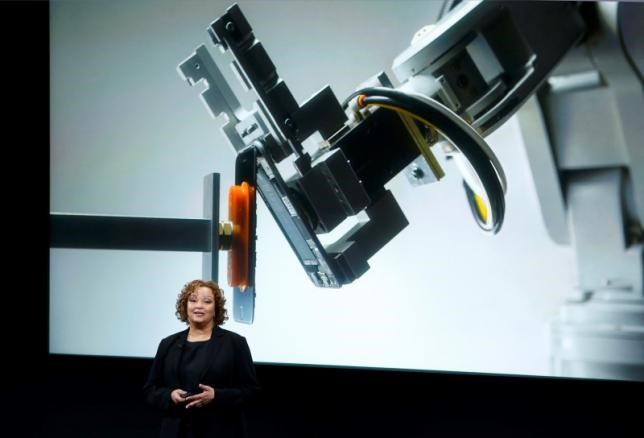

| Lisa Jackson, Apple vice president for Environment, Policy and Social Initiatives, introduces a robot named Liam that deconstructs iPhones during an event at Apple headquarters in Cupertino, California March 21, 2016. |

Apple Inc on Monday unveiled a robotic system called Liam to take apart junked iPhones and recover valuable materials that can be recycled, such as silver and tungsten.

The move is an attempt to address criticism that Apple's products, while sleek and seamless in design, are so tightly constructed that their components can be difficult to disassemble, refurbish and reuse.

Liam, which has been under development for nearly three years, will initially focus on the iPhone 6. Apple plans to modify and expand the system to handle different devices and recover more resources, the company said.

The system started to operate at full capacity last month and can take apart one iPhone 6 every 11 seconds to recover aluminum, copper, tin, tungsten, cobalt, gold and silver parts, according to Apple.

At that rate and working uninterrupted, Liam likely can handle no more than a few million phones per year, a small fraction of the more than 231 million phones Apple sold in 2015.

Greenpeace welcomed Apple's initiative as an example of how the company is committed to keeping more products out of land fills, but the environmental group questioned how much of an impact the Liam robot would actually have on overall iPhone recycling volumes.

Independent e-waste recyclers, which handle the bulk of discarded iPhones, will not have access to Liam.

"If it's easy for a robot, that's great," said Gary Cook, senior IT analyst for Greenpeace. "But making it easier for a human, who will be doing most of this, is part of the solution."

Greenpeace urged Apple to build more products using recycled metals, and to make its devices easier to deconstruct. Cook said Apple has been an industry leader on some environmental issues, such as asking suppliers to run on renewable energy.

"A lot of the sector has followed their lead because they've helped change the supply chain," he said.

Another robot in Europe

The world is awash in discarded electronic equipment, with the United States and China accounting for nearly a third of it. Less than a sixth of global e-waste is properly recycled or made available for reuse, according to an April 2015 United Nations University report.

Apple does not disclose how many of its devices are turned in for recycling every year. Under its existing program, the company offers customers store credit for recycling certain devices and will recycle old products for free.

The Liam system consists of 29 robotic modules on a single site near Apple's headquarters in Cupertino, California. It will focus initially on iPhone 6 phones sold in the United States, where Apple gets about 40 percent of its revenue.

A second Liam is being installed in Europe, Apple said.

Lisa Jackson, Apple's vice president of environment, policy and social initiatives, said Liam can help push the technology sector toward more recycling, by manufacturers and consumers.

"We need more R&D if we are going to realize the idea of a circular economy in electronics," she said.

Jackson, who was U.S. Environmental Protection Agency administrator from 2009 to 2013, spoke to Reuters before she unveiled Liam at Apple's spring product launch on Monday.

Some environmental activists have criticized Apple for not making its products more green. In the ultra-thin MacBook Air, for instance, the chips, hard drive, battery and processors cannot easily be upgraded. The units use bespoke screws or glue to hold them together.

Computers made by other companies tend to be more modular and easier to break apart.

Kyle Wiens, co-founder of iFixit, an open-source repair manual for devices, said one reason iPhones, iPads and iPods are difficult to pry apart is that their batteries are glued into the devices.

A large number of older iPhone models are resold to consumers in China and parts of Africa, which have more limited recycling options. Putting robots in California and Europe may not address that problem, he said.

"It's notable that they (Apple) are talking about this, but unless you get one of these robots inside every recycler in the world, it's not going to have an impact," Wiens said.

"On the one hand there is this really cool robot, and that's great. On the other hand there are a lot of realities on the ground that will make this not really have an impact," he added.

Jackson said Apple's design approach will not change, but the company is working on better ways to disassemble its devices and recover reusable materials.

(Source: Reuters)