Supporting industries are the foundation for sustainable development, not only providing raw materials for many other industries but also enhancing the competitiveness of finished industrial products. Developing supporting industries is a key solution to achieving industrial self-sufficiency in Vietnam's future.

|

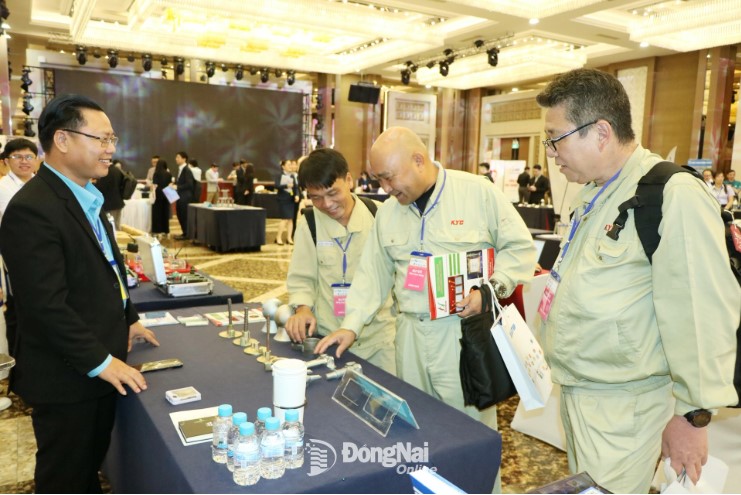

| Vietnamese supporting industrial products will participate in the Vietnam-Japan Business Matching Program organized by the People's Committee of Dong Nai province at the end of November 2025 |

Currently, supporting industries have many opportunities to integrate into global supply chains. However, challenges related to capital, technology, and international standards remain significant barriers, necessitating more substantial and long-term support policies to address the immediate needs of manufacturers and foreign direct investment (FDI) enterprises operating in Vietnam.

Solving the problem of business competitiveness

According to the Center for Industrial Development Support under the Department of Industry (Ministry of Industry and Trade), there are currently nearly 7,000 supporting industry enterprises nationwide. Among them, enterprises producing components and spare parts play a crucial role, supplying the manufacturing sectors of automobiles, motorcycles, mechanical engineering, electrical engineering, and electronics. Several sectors have achieved a relatively high localization rate, creating a competitive advantage over imported products.

However, from an overall perspective, the localization rate in many industries remains low, at only about 30-40%, falling short of the government’s target of 50-60%. The competitiveness of Vietnamese enterprises remains constrained by limitations in science and technology, engineering capacity, and access to technology and capital, which in turn results in a weak independent innovation capacity.

In Dong Nai province, for many years, the province has focused on developing supporting industries to take advantage of opportunities for cooperation in supplying raw materials and components to FDI partners. Programs connecting directly with foreign businesses in the area have initially proven effective.

According to Ngo Thanh Binh, Director of Quyet Thang Production and Service Trading Company (based in Tran Bien ward), the company has expanded its network of FDI partners by participating in business networking programs and other connection support solutions, thereby increasing its supply of automated machinery products.

Experts note that, in practice, although policies are in place to support industry development, they often remain inconsistent. Existing regulations related to the supporting industry sector are mainly at the decree level and dispersed across various laws, resulting in a lack of coherence and making it difficult for many preferential policies to be effectively implemented. This challenging reality underscores the need for the early introduction of a robust, standalone law that supports industries in establishing a prioritized legal framework, eliminating administrative barriers, and fostering the substantive development of the sector.

Connecting for growth

To develop, supporting industry enterprises must first and foremost connect and collaborate. A notable example is the Truong Hai Group, which is building a specialized industrial park to support industries in the Southeast region. Truong Hai is investing in a new-generation industrial park model, focusing on large-scale, centralized production and management based on industrialization and digitalization, while also strengthening linkages and cooperation with domestic and foreign enterprises to maximize resource utilization. This model is expected to create a complete value chain that meets export standards, enhances competitiveness, supports industry development, and contributes to building a self-reliant industrial base for Vietnam.

To develop supporting industries, enterprises must proactively improve their technical and financial capacity. At the same time, the State must allocate resources appropriately and issue policies that have a tangible impact on the sector.

According to Truong Thi Chi Binh, Vice President and General Secretary of the Vietnam Association of Supporting Industries (VASI), the association is developing a comprehensive action plan to expand the industry's production capacity. VASI recommends that businesses focus on cost management, select appropriate customer segments based on scale and sector, diversify partners, and expand production processes from supplying individual components to component assemblies, aiming to supply products under their own designed brands.

It is not enough to connect domestic enterprises with one another; it is also essential to establish linkages with FDI partners, as demand from these partners is substantial. According to Yamamoto Ryo, Director of Takashima Metal Precision Vietnam Co., Ltd. (located in Long Duc Industrial Park), the company prioritizes on-site procurement to help customers reduce logistics and import costs while leveraging the domestic supply network. To increase the localization rate, enterprises will work with qualified Vietnamese suppliers to provide raw materials, semi-finished components, and finished products for their production processes.

According to Nguyen Huu Duc, Deputy Head of the Dong Nai Industrial Support Coordination Team, the team will continue to introduce local suppliers to FDI partners, while also supporting the resolution of administrative procedure bottlenecks in production and business activities. The exchange of information between FDI enterprises and domestic businesses will create opportunities for connection, cooperation, and the expansion of the local product supply chain.

By Vuong The – Translated by Quoc Dung, Minho

Thông tin bạn đọc

Đóng Lưu thông tin